Microswitch Terminology?

"Micro Switches" are manufactured by a wide range of companies and have been around for many years. Although "Micro-Switch" is used to refer to many types of snap action switches, the trademark is owned by the Honeywell Corporation (who purchased the trademark from the real inventor).

Micro-Switches - How Do They Work?

Operation typically beings with the application of a small force through a stiff metal actuator strip which produces a small, adjustable displacement. When released, the Micro Switch flips backs with a high speed using hysteresis making the activation force higher than the deactivation force. This quick movement of the metal strip is responsible for the characteristic clicking sound.

Making Micro Switches Waterproof

One can use waterproof micro-switches in many applications including in a rugged high humidity environment and military or space applications where extreme temperatures exist. The primary benefit of these switches is that of maintaining seal integrity over potentially millions of switch activations. Moreover, to achieve a stable approach that meets all requirements, requirements of high electromechanical endurance, must be traded off against the type of actuator and the conflicting goals of start-up current requirements, cold or hot temperature performance, normally open/closed configuration, and many other design parameters.

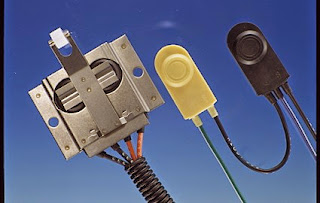

Micro-Switches by CPI

- Our microswitches are designed and made in the United States. This commitment to US manufacturing allows us to control quality of manufacturing to a degree that our offshore competitors can't match. All our products are tested and built and designed in our East Hanover NJ facility.

- Our switches are not just water resistant or splash proof, they are fully waterproof. For a high electromechanical performance, extended (mil-spec) temperature range and low production costs, a completely sealed switch enclosure of either neoprene or santoprene is applied. We use a proprietary manufacturing process to do this, developed over years of trial and error, and massive use in the field.

- To prevent contaminants in the assembly, Ball and Plunger switches use a patented ball carrier design. These switches are among the most rugged of their kind in the world.

- 60 years of experience in custom switch engineering means there are few requirements we can't design for and achieve. Our engineers will customize and qualify your switch directly inside your application providing you with all required analysis and documentation.

Our unique value-add in the micro switch market stems from a few primary competitive differentiators.

For more information on CPI Waterproof Micro Switches, call our team today to discuss your application or visit our website at http://www.cpi-nj.com

Comments

Post a Comment